We love data at Modjoul. We talk most about how we measure and analyze a range of ergonomic factors that directly impact worker and overall workplace safety.

The reliable, actionable data we gather through our SmartBelt Safety Wearable enables us to analyze worker movements. This then becomes the basis of our ongoing work with clients to target additional training where it is needed and reduce the risk of workplace injuries.

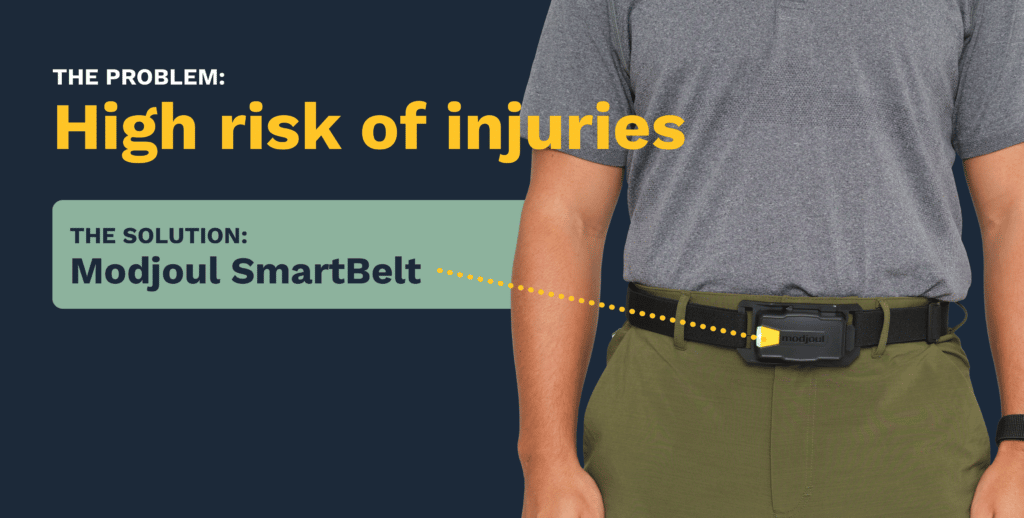

We also are constantly measuring and analyzing the SmartBelt itself. Our goal is to understand how the SmartBelt’s usage impacts worker movements. Indeed, businesses we work with are keenly interested in the topic of “time-worn data.”

Specifically, we usually hear a variation of the following two questions:

1. How long after our workers start wearing the SmartBelt will we see improvements?

2. How long will we continue to see improvement in ergonomic performance and overall safety?

Wearing the SmartBelt = Immediate Improvement

From the moment workers receive additional ergonomic training, are introduced to the SmartBelt, and start wearing it, there is a reduction in the kind of risky movements that can lead to workplace injuries.

Simply wearing the SmartBelt can generate an added awareness that leads to improved ergonomics and lower risk of injury. Even before the haptic response is turned on, the SmartBelt serves as a physical reminder of what each worker is trying to accomplish in terms of proper physical movements and workplace safety.

“We try to establish a baseline with each customer of what their movements look like pre-Modjoul, but the very fact they have a device on means that baseline is not exact,” explains Modjoul Data Scientist Collin Davies, PhD. “Day 1 behavior is not the same as before, because the wearer is more mindful. And as long as they wear the SmartBelt, the data shows they continue to be more mindful of safety going forward.”

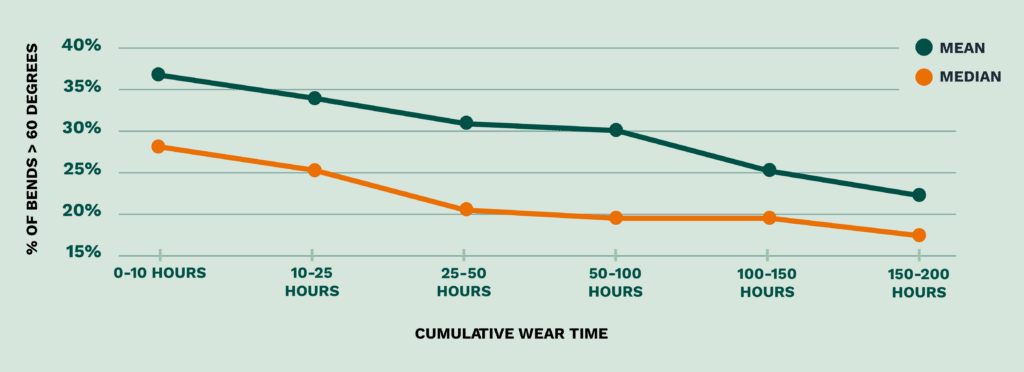

Bends of 60 degrees or more — essentially when a worker bends over at the waist rather than using their legs to pick up an item — are one of the riskiest movements and a leading cause of workplace injuries. As such, Modjoul closely tracks these movements.

After just 10-25 hours of wearing the SmartBelt, the median value of the percent of risky bends in the workplace declines. During this initial, or baseline, period of time (usually 1-2 weeks), workers “essentially are learning new muscle memory or routines,” Davies said. “That’s why we think the consistent wear for the entire duration of a shift is essential to seeing the type of improvement these companies are interested in.”

Why Time-Worn Is Best Predictor of Improvement

While improvement in the median value slows beyond 100 hours of wear, the mean value continues to improve well beyond 200+ hours of wear time. This result captures the impact of the Modjoul SmartBelt system for workers with different feedback sensitivities and starting points.

For example, for employees who have the most room to improve their physical mechanics and ergonomics, a significant reduction in their risky bends continues beyond 200+ hours of wear time. Training and helping workers who are most at risk of hurting themselves is an important part in maximizing the impact of the Modjoul SmartBelt system. Our data analysts can help you develop a comprehensive plan to address your unique risks.

And it’s not just the total number of hours that is important — it’s the consistent usage of the device that yields the best results, Davies said.

“Consistent use of the Modjoul wearable is the leading indicator if they are going to improve,” he said. “If you wear it each day, that’s good, but if you wear it for the full eight hours of your shift, that’s better.”

Ongoing use of the SmartBelt allows companies to continue to help workers who have the most room for improvement or who need extra help. That’s why it’s essential to study and analyze performance not just in terms of the mean (average) but the median (the value at which 50 percent is above and 50 percent falls below).

“Just like any type of feedback, some people respond quickly to it, and some people respond more slowly. What we have is a bell curve with a really long tail. That long tail represents that there are a few people who have a lot of room for improvement. A lot of people improve after 100 hours, but some people improve at a slower rate over a longer period of time.”

Those workers ultimately face a higher risk of being injured. In that sense, the Modjoul SmartBelt is tailored to help them the most.

“But it is hard to identify who those workers are at first,” Davies said. “We are giving our clients a window to access that information, which they didn’t previously have. Before Modjoul, many of our customers had little or no insight into body movement and the associated risk. Now they do.”