Roughly a year ago, Modjoul announced our new forklift safety system and started to introduce it into workplaces that were seeking a better way to protect workers. Because some of the most devastating worker injuries are the result of forklift accidents and collisions, there has been significant interest in this new solution.

While every workplace is different, there are some questions that apply nearly across the board. So we sat down with Client Strategy & Solutions Manager Hunter Burgett to talk about our forklift safety solution. And we would welcome the opportunity to dive deeper into your specific situation and discuss how Modjoul’s forklift safety solution fits into your overall workplace safety approach!

Question: Walk through the setup of the Modjoul forklift safety system. How long does it take to get the system integrated into a workplace?

Hunter Burgett: Our setup process is very streamlined to minimize the amount of downtime to a company’s forklift operations. Installation takes 15-20 minutes per forklift. The installation process starts with identifying the ideal position for both the forklift module (antenna) and driver box. Once identified, two clamps are put in place to secure the forklift module and driver box to the forklift. After this is completed, the power cable is tied into the forklift power system using wire tappers. This eliminates cutting any of the forklift wires and speeding up the installation process.

Q: What has Modjoul learned about forklift accidents? What are some common underlying causes?

HB: Even with companies limiting their speed, forklifts travel much faster than people walk. This significantly reduces the amount of time for a pedestrian to react when they find themselves in a dangerous position. Many facilities must maximize the amount of space they have. As a result, aisles can be narrow and there are often racks stacked much higher than an average person’s height. This can cause blind spots throughout facilities, which leads to more risky interactions between people and forklifts.

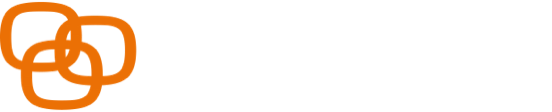

Q: How much equipment/how many pieces of equipment are a part of the Modjoul system? What does each do?

HB: There are three major components of the Modjoul system:

- Forklift Anchor Module (antenna): This houses the PCB and antennas for the forklift system. The antennas use Ultra-Wide Band (UWB) technology to communicate with the wearable and detect when they are in proximity to each other.

- Driver Box: Connected to the forklift anchor module, the driver box provides both audio and visual alerts to the forklift operator. When a pedestrian or another forklift enters the low proximity zone, a yellow screen appears with an exclamation mark, signaling that a pedestrian or forklift is nearby and to be alert. A red screen with an ‘X’ will appear accompanied by an audible warning whenever another forklift or pedestrian has entered the high proximity zone. This level of warning should be used by the driver to use extreme caution and be aware of their surroundings because another forklift or pedestrian is very close, even if they are unable to see them (view obstructed by rack for example).

- Wearable: Our wearable is worn by pedestrians. They can be worn in multiple locations to best serve the user (belt, vest pocket, lanyard holder). The wearable also uses UWB technology to communicate with the forklift system. Pedestrians with the wearable will receive an alert in the form of a vibration, an audible warning tone and a flashing light once they enter the high proximity zone.

Q: What kind of data does the forklift system provide?

HB: The system measures the number of high and low interactions between forklifts and forklifts to pedestrians. The system also measures forklift utilization time (% used in a 24-hour period).

Q: What kind of results have you seen so far?

HB: The UWB chip provides extremely accurate results in the workplace and provides confidence to our customers. In addition to closely monitoring the safety of associates, the comprehensive data acquired also facilitates the assessment of forklift efficiency and productivity.

If you would like an assessment of your workplace risks or to see a demo of any of our solutions, we would love to start a conversation with you. Complete the form below and one of our client strategy and solutions experts will be right back in touch!